Retired railroad ties have caused disposal problems for decades, but TiEnergy found a way to turn problems into products. The 22 million railroad ties that go out of service each year were historically difficult to responsibly remove and recycle, and there was no demand for the very generous supply of old railroad ties. By inventing a new process and creating a new product, TiEnergy connected supply to demand, solved an ongoing problem for railroads, and developed an environmentally friendly solution that supports sustainability goals. Here’s a behind-the-scenes look at the steps TiEnergy took to create a market demand for old railroad ties and give them a second life:

Assess the Problem: TiEnergy first took stock of the situation. There was no ideal or easy solution to properly dispose of retired ties. The primary methods at the time were incineration or burning. Standard landfills aren’t able to accept old ties since they can wreak havoc on their equipment, the metal hardware makes it difficult to grind them up, and simply moving them from place to place only transfers the problem. What could be done?

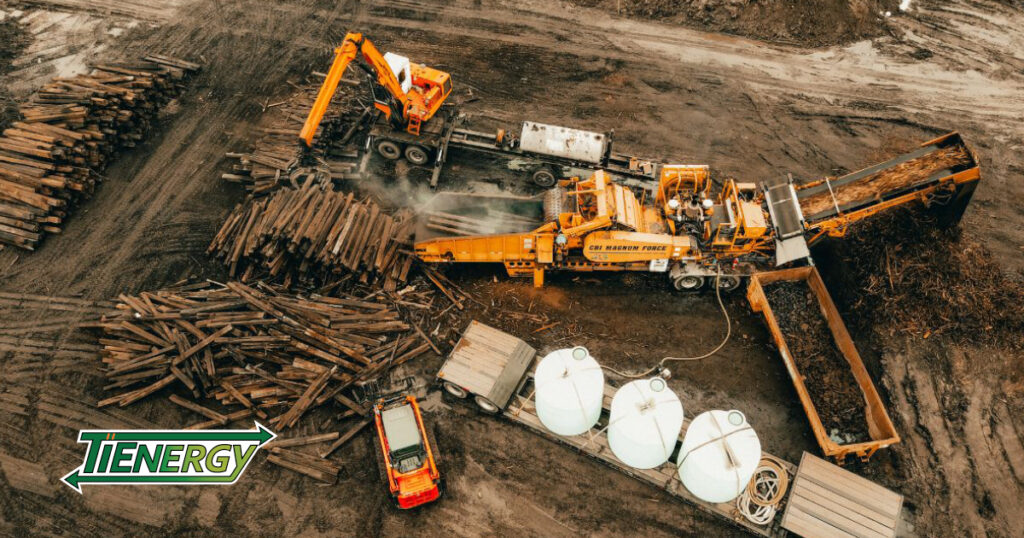

Develop a Strategy: TiEnergy took a closer look at the no-burn methods of disposal. Since metal hardware was preventing ties from being ground up, it made logical sense to consider a way to remove the tie plates and bolts easily and efficiently. TiEnergy tested, perfected, and patented a new machine called the Tie Plate Picker that removes metal rail fastening hardware such as tie plates, spikes, and rail anchors from the wood. The wood-only ties could now be ground up. The only question was what to do with them.

Identify an Opportunity: The process could have stopped here, with ground ties simply being disposed of in the landfill, but TiEnergy kept going. Landfills typically use construction aggregate (composed of materials like stone, rock, and sand) as the substance to line their roadways for truck deliveries. This heavy substance is carbon-intensive to ship and deliver and causes significant wear and tear on trucks. TiEnergy recognized an opportunity to turn ground ties into an aggregate substitute for landfills. A new product was born.

Create a Solution: The new product, TIEROC, is an aggregate substitute primarily made of old ties that streamlines landfill operations. The company grinds up close to 5,000 ties per day, relieving the railroads of the burden of managing them. The TIEROC product itself creates lighter, smoother roadways for landfills that require fewer carbon-intensive shipments to deliver and are easier for the trucks to navigate – preventing operational delays from stuck trucks and equipment depreciation from wear and tear. Once the roadways are no longer needed, TIEROC can simply be sustainably buried in the landfill.

Launch a Market: Word spread across railyards and landfills. The Tie Plate Picker and TIEROC transformed the problem of old ties into a solution for multiple economic, environmental, and operational issues. TiEnergy created a whole new market demand for old railroad ties that didn’t exist before, and established railroads at the center of a new circular economy.